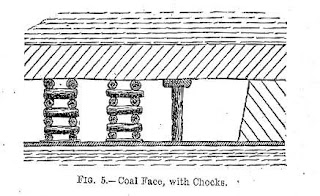

Timber support for different places in mine

Timber support in coal mine Side Support: Wooden laggings are placed tight between vertical props and pillar where the sides are weak and need support. Sometimes the timber set of prop and bar has to resist pressure from sides which tend to crush into the roadways. Notching is useful in such cases. The props should be set at an angle of 14° to 20° off the vertical and the feet well sunk into the floor. An alternative method of resisting side pressure is to sink the props well into the floor and to reinforce the timber-set by an additional bar or stretcher (dotted bar in fig), which may be nailed to the props. As this reduces effective height of roadway, its use may not be advisable in roadways of less than 2 m height, used by basket loaders. Reinforced Timber set or chockmate Notched Prop Support of a Roadway: Where the roof of a roadway is bad over some distance bars resting in holes of coal pillars and tightened against the roof by wooden laggings may be erected