life-cycle assessment (LCA)

A life-cycle assessment (LCA, also known as life-cycle analysis, ecobalance, and cradle-to-grave analysis) is a technique to assess environmental impacts associated with all the stages of a product's life from-cradle-to-grave (i.e., from raw material extraction through materials processing, manufacture, distribution, use, repair and maintenance, and disposal or recycling).

LCA’s can help avoid a narrow outlook on environmental concerns by:

- Compiling an inventory of relevant energy and material inputs and environmental releases;

- Evaluating the potential impacts associated with identified inputs and releases;

- Interpreting the results to help you make a more informed decision.

|

| Life cycle assessment |

PGM LCA

Based on the IPA LCA (international platinum group metal association – life cycle assessment) study of the PGMs life-cycle assessment, the below mentioned benefits and impact were found.

I. Impacts

a. Electricity demand

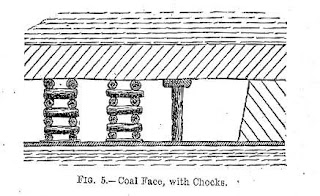

Power consumption during mining and ore beneficiation has been identified as the major impact of the production of PGMs on the environment. This is due to the low grade of ore and difficult mining conditions as well as the composition of the South African power grid where more than 90% of electricity is produced from burning hard coal.

b. RECYCLING REDUCES IMPACT

The results indicate that, as is often the case, secondary production has a much lower impact than primary production. This is expected for various reasons, including the vast difference in the concentration of PGMs between primary and secondary sources.

c. GWP / PED (global warming potential / primary energy demand)

GWP is calculated in Kg CO2 – eq/g (kilogram of carbon dioxide equivalent per gram of PGM produced/processed). Carbon dioxide equivalent (CDE) and Equivalent carbon dioxide (CO2e) are two related but distinct measures for describing how much global warming a given type and amount of greenhouse gas may cause, using the functionally equivalent amount or concentration of carbon dioxide (CO2) as the reference.

PED calculated in MJ/g i.e. Mega or million Joule of Energy required pre g of PGM produced or processed.

|

Global warming potential & primary energy demand

of PGM

|

II. BENEFITS

a. AUTOCATALYSTS

The emissions reductions as a result of the use of a catalytic converter outweigh the emissions generated during the production of the catalyst including PGMs and other related materials used to support the functionality of the catalyst

b. CO / HC / NOX / PM

Over 1.3 tonnes of toxic and harmful pollutants including carbon monoxide, hydrocarbons, oxides of nitrogen and particulate matter are avoided by the catalytic converter systems in one EURO 5 gasoline and one EURO 5 diesel vehicle in use over 160,000km; this is equivalent to a reduction in these emissions of up to 97%.

Since 1992, European Union regulations (EURO 1 to EURO 6) have been imposed on new cars, with the aim of improving air quality. Catalytic converters became compulsory on new cars.

Carbon monoxide (CO): petrol down 63%, diesel down 82% since 1993

Hydrocarbons (HC): petrol down 50% since 2001

Nitrogen oxide (NOx): down 84% since 2001

Particulate matter (PM): diesel down 96% since 1993

c. HEALTHY LIFE

The positive effect of emissions reductions can be quantified using the World Health Organization’s (WHO) metric of Disability-Adjusted Life Year or DALY. A DALY is used to quantify the burden of disease or morbidity on human life.

|

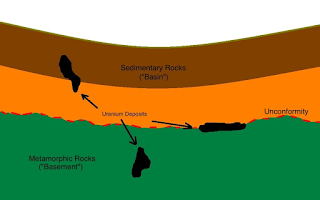

Life assessment diagram of PGMs

|

keywords: what is life cycle assessment?, what is the benefit of life-cycle assessment (LCA)?, life assessment of PGMs. Autocatalysts,

Comments

Post a Comment