Different types of timber support

Different types of timber supports

Timber props

Timber placed normally between the roof and floor of roadways, etc. in coal mines is called timber prop. Timber prop in metal mines is sometimes called stull. A timber prop when erected in a mine to support the roof should yield slightly under the roof weight. The timber prop is strongest when the load acts parallel to its length; a prop as such is almost unyielding but a certain yield is obtained by;

a) tapering it at the foot or top, or

b) and providing a lid at the top as a compressible cushion between the roof and the end of the prop.

In flat seams the prop is erected vertical, and in inclined seams, axis of the prop should be normal to the dip of the seam. The prop then offers the maximum resistance to the roof. A prop which is so set that its axis is between the vertical and the normal to the seam is known as and underset prop. Erection of underset props is not common as it is not possible for the timberman to judge whether it is underset or not. Fig.

Prop should be set on solid floor and not on loose packing or debris accept in case of emergency. If the prop has to set on loose rock, loose coal, or sand pack, it should be placed on a flat base piece not less than 5cms thick, 25cms wide, and 0.9ms long. Such props on loose coal or rock should, however, be removed as early as possible and replaced by props erected on solid floor after cleaning up loose rock or coal. If the floor is soft, the base piece or foot lid mentioned here is used to prevent prop penetration in the floor.

|

| Underset prop |

Setting up props.

Prop is held upright in the place where it is to be erected, a lid is placed on top of it (not nailed), and a wedge is hammered between the lid and the prop to tighten the lid against the roof and the floor. Fig. Sometimes, for lower heights of up to 2.5m the lid and wedge are not used as two separate pieces, but the lid is so made (slightly tapering along the length), that is serves the purpose of a wedge also. If there is any crack or slip which needs support the lid should be placed across the crack or slip. A timber prop is expected to support a roof area of about 0.4m to 1 m all around.

A lid serves to distribute the resistance of the prop over a slightly wider are than its cross-section, to prevent penetration of the prop into the roof, and to indicate the load on the prop. It also helps easy withdrawal of the prop. Wedges are used to tighten the prop against the roof and the floor. The lids and the wedges should be at least of the same width as the diameter of the prop, of a minimum thickness of 80mm and of a length of 0.5m.

For heights of roof where timber men cannot reach to (usually above 2.5ms): there are two methods

i. The position of the bottom end of the prop on the floor corresponding to the place in the roof to be supported is marked by a plumb bob suspended from the place in the roof to be supported. The prop is held upright by 2 or 3 timber helpers. The timber man standing on a high stool or a ladder places the lid and a wedge is hammered on a position.

ii. The more convenient/simpler method where no stool or ladder is required to be carried place to place for prop erection, is: a lid is attached to the prop by nails and a hole is made nearly 25mm deep in the floor, where the bottom end of the prop is to remain after erection. The prop laid on the floor with the bottom end in the hole, is made upright, the hole preventing the prop from sliding.

The prop is held in position by timber helpers and one timber helper levers up its bottom end by a craw-bar bringing the lid in contact with the roof. A wedge is then hammered between the prop and the floor to tighten the lid against the roof.

In inclined seams, steeper than 1 in 5, it is usual to fit the foot of the prop into a stamp hole in the floor.

|

| Setting a prop |

|

| fork for holding a prop |

Tapered props:

About 200 to 500mm length of one end is tapered, and the other end is provided with a lid. Tapered end should be in contact with hard surface. The props are used where the floor is hard and the roof is soft. With increasing roof pressure the tapered end burrs and provides yielding.

|

| Tappered prop |

Timber bars

Bars act as beams. A timber bar is placed in the holes of minimum depth of 500mm in the side of a coal pillar if the sides are strong. If the sides are weak, the bar is placed on vertical props. If the bar is circular in cross-section, the top end of the prop should be hollowed out to fit the contour of the bar. Alternatively, the bar may be flattered at each end so the ends can rest on the flat end of the props. The bars should be tight against the roof and should offer the maximum area of contact against it. Flat wooden laggings are also used if the roof is uneven.

|

| Timber bars |

Safari supports

The conventional method of supporting galleries in coal mine is by means of wooden crossbars. For fixing these crossbars, holes are to be made in the coal pillars manually by crawbar. This is time-consuming and the whole operation of fixing one crossbar takes about 2 to 2.5 hours. Therefore the supports lag much behind the work face. For quick setting of the crossbars, the manual cutting of holes in the coal pillar is eliminated by drilling holes with the usual coal drills and a support, known as safari support, is installed to support the roof. This support consists of a pair of clamps of mild steel on which a crossbar is placed to support the roof. Each clamp consists of an angled iron frame to which semi-circular mild steel bracket is welded as a seat for the wooden crossbar, and in the angle iron two holes of 35mm diameter and 175mm apart, are provided for two mild steel rods of 32mm diameter and 700mm long. The two mild steel rods of each clamp are inserted into the holes drilled in the coal pillar. The crossbar is placed over the two brackets and tightened against the roof with wooden wedges.

The complete operation of setting the support is completed within 15 to 20mins for each crossbar. The clamps can easily be recovered and reused for several times. The support stands the effects of blasting and freshly exposed roof is supported in short time after exposure. One of its application is to support split galleries in depillaring areas in thick seams and extract the floor coal, heightening the galleries up to 5 meters. During the extraction of stooks, wooden chocks are provided in the split galleries and later on the clamps are recovered completely for reuse.

Safari supports require strong coal pillars. In thin seam, the effective height of the gallery is reduced which is a disadvantage where coal- loaded baskets have to be carried on head for tub loading.

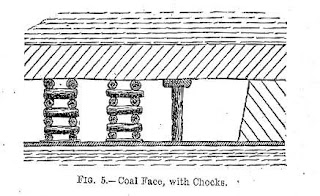

Wooden Cog, Chock or Crib

A chock, cog or chockmate is a combination of sleepers above one another in a criss-cross manner as shown in fig. It supports a much larger stretch than a prop and is used in places where the roof is bad over a wide area and needs substantial support. Cogs are also erected where main roadways have to pass through area having coal pillars of inadequate size. The term chockmate is generally used in metal mines.

Cogs are required under the regulations at goaf edges, at junctions of splits and galleries in depillaring areas in bord and pillar workings, and at break-off line at the goaf on longwall faces.

Only rectangular sleepers, or alternatively, sleepers having their two opposite sides, chopped flat, should be used. The minimum length of sleepers of a cog so support roof at a height up to 3m maybe 1.2m but for roof height excess of 3m it maybe 1.5m. The sleepers should have a minimum cross-section of 100mm X 100mm.

The cog should not be normally erected on loose floor or debris, but on natural floor or on a secure foundation. The floor area over which the cog is to be erected may be excavated for a depth of 25 to 50mm and should be made nearly flat in seams of mild inclination. Members of the cog are placed at right angles over the members immediately below in pairs. The chock is tightened against the roof by hammering wedges in it at a convenient height. When withdrawing a chock, withdrawal of such wedge loosens the chock and withdrawal of the sleepers becomes easy.

The chock should be tight against the roof and this may be tested by hammering for looseness at the uppermost sleepers.

In some cases, a chock is erected in between four corner props. Such corner props are generally not necessary except: a) where roof is very bad, b) at goaf edges of galleries, c) at junctions of galleries and d) if the floor is steeper 1 in 5. Where corner props are erected, one sleeper of the chock is always placed outside the prop. Withdrawal of the member helps to dismantle the chock.

|

| Wooden Chock/Cog/Crib at the coal face |

|

| wooden crib/chock/cog |

|

| Crib blo |

Comments

Post a Comment